Although we believe most all of the parts for the MICHIGAN are all here, we were told by the prior owner, Steve Dickey, that the radiator cap has been missing for years. Something about a motorcycle gang getting in the barn and taking some random stuff. Seriously, I didn’t make that up.

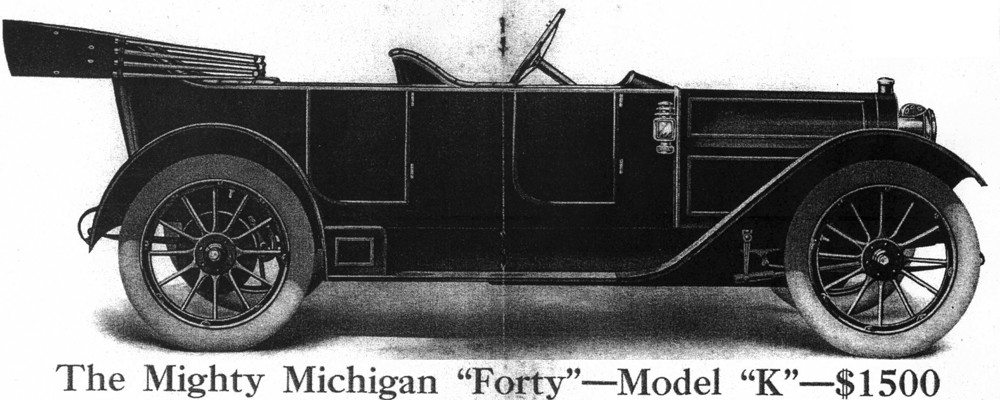

Anyway, that meant that we needed a radiator cap. OK…… so are radiator caps for MICHIGANs easy to find? Can we really figure out what they look like? So, we need to look at photographs of other MICHIGAN automobiles. Ah….. that is easier said than done. Michigan’s are few and far between. And photos of MICHIGANS taken in 1912, or thereabouts are SUPER rare. The MICHIGAN MOTOR CAR COMPANY seemed to like to put high quality drawings or illustrations in their literature. NOT PHOTOGRAPHS. And the illustrations are not very helpful. The illustration below is a drawing from page 17, of the “MICHIGAN AUTOMOBILES 1912” sales brochure. What we see is a plain cap with indentations for fingers. It is difficult to see how tall or short the cap may be. Nor is it possible to determine the material it is made of or its color.

So, over the past several years I’ve tried to see what other Michigan owners have on their cars. So here are a collection of photos that shows what radiator caps are on existing MIGHTY MICHIGAN 40’s. The silliest looking radiator cap is one I found on the internet that is in an Italian registry of current and defunct automobile “mascots” or “marques” (brand logos). This one below incorporates a very fancy Union shield decorated “dog-bone” handle, a Boyce brand “Motometer” thermometer and a ridiculous diving imp or fairy. I believe that this particular conglomeration of stuff is not remotely authentic.

So, over the past several years I’ve tried to see what other Michigan owners have on their cars. So here are a collection of photos that shows what radiator caps are on existing MIGHTY MICHIGAN 40’s. The silliest looking radiator cap is one I found on the internet that is in an Italian registry of current and defunct automobile “mascots” or “marques” (brand logos). This one below incorporates a very fancy Union shield decorated “dog-bone” handle, a Boyce brand “Motometer” thermometer and a ridiculous diving imp or fairy. I believe that this particular conglomeration of stuff is not remotely authentic.

The other photos I’ve collected of radiator caps are not nearly so extravagant (or silly).

The other photos I’ve collected of radiator caps are not nearly so extravagant (or silly).

The earliest is from Loren & Louise Cuthbert’s 1911 MICHIGAN, car number 1001, It has a set of wings, a Boyce Motometer and a flip top cap.

The next is from Mike & Nancy Howard’s 1912 Model K, car number 3477. This has a simple cap painted black and a Boyce Motometer. The cap shows no finger notches, as depicted in the MICHIGAN AUTOMOBILES 1912 brochure.

The next is from Mike & Nancy Howard’s 1912 Model K, car number 3477. This has a simple cap painted black and a Boyce Motometer. The cap shows no finger notches, as depicted in the MICHIGAN AUTOMOBILES 1912 brochure.

I received photos of the car once owned by Jim & Loretta Cesari, car number – unknown (now owned by ???). The cap does have the finger notches, and also a Boyce Motometer showing one of several “MICHIGAN” logos that appears in sales literature. The cap is brass and so is the radiator shell and much of the car’s trim which does not seem to be consistent with contemporaneous sales materials claiming the cars had more expensive white nickel mountings and trim.

I received photos of the car once owned by Jim & Loretta Cesari, car number – unknown (now owned by ???). The cap does have the finger notches, and also a Boyce Motometer showing one of several “MICHIGAN” logos that appears in sales literature. The cap is brass and so is the radiator shell and much of the car’s trim which does not seem to be consistent with contemporaneous sales materials claiming the cars had more expensive white nickel mountings and trim.

This last photo is from an R&M Auction promotion in 2008, of the sale of a 1913 MICHIGAN Model R, the most expensive and last of the MICHIGAN cars ever produced. Car number – 5881, purchased in Iowa by Dr. Art Burrichter in 1992 and later restored by Silver Dollar Restoration in Tampa FL. This radiator cap is simple, painted black and has the finger notches that show up in the literature. The car sold for $154,000. It is unknown if the radiator shell was originally nickel plate or this was a later addition.

This last photo is from an R&M Auction promotion in 2008, of the sale of a 1913 MICHIGAN Model R, the most expensive and last of the MICHIGAN cars ever produced. Car number – 5881, purchased in Iowa by Dr. Art Burrichter in 1992 and later restored by Silver Dollar Restoration in Tampa FL. This radiator cap is simple, painted black and has the finger notches that show up in the literature. The car sold for $154,000. It is unknown if the radiator shell was originally nickel plate or this was a later addition.

Last year I purchased a 1913 Salesman’s Book which contains only illustrations on heavy fabric backed paper. The illustration below is in the book and shows what the front of the car as it would have been in 1913. Of all the caps I’ve got pictures of, the 1913 Model R seems to be the most original in appearance. Someday I may even find one. By the way the size of the cap is 18 threads per inch and 2.06 inches for the minor diameter on the threads.

Last year I purchased a 1913 Salesman’s Book which contains only illustrations on heavy fabric backed paper. The illustration below is in the book and shows what the front of the car as it would have been in 1913. Of all the caps I’ve got pictures of, the 1913 Model R seems to be the most original in appearance. Someday I may even find one. By the way the size of the cap is 18 threads per inch and 2.06 inches for the minor diameter on the threads.

Because I haven’t been able to find a radiator cap (the radiator is made by the CANDLER company of Detroit), I’ve put my very modest lathe experience to the test on a solid block of aluminum. (Sort of looks like nickel trim.) Because I don’t have a milling machine, I dispensed with the finger notches. Don’t ask how many hours it took.

Because I haven’t been able to find a radiator cap (the radiator is made by the CANDLER company of Detroit), I’ve put my very modest lathe experience to the test on a solid block of aluminum. (Sort of looks like nickel trim.) Because I don’t have a milling machine, I dispensed with the finger notches. Don’t ask how many hours it took.  Because I needed lathe practice — I made two caps. So if one goes missing – I’ve got a spare!

Because I needed lathe practice — I made two caps. So if one goes missing – I’ve got a spare!

Here’s a photo with the new cap on the radiator — a model very similar to the Candler Model — the Candler Special “King” — (I’ll attach the brochure for Candler Radiator Company in the Nuts & Bolts section.) NOTE — our radiator is NOT BRASS. NOT NICKEL. Just painted black. No insignia. No medallions. No name.

Here’s a photo with the new cap on the radiator — a model very similar to the Candler Model — the Candler Special “King” — (I’ll attach the brochure for Candler Radiator Company in the Nuts & Bolts section.) NOTE — our radiator is NOT BRASS. NOT NICKEL. Just painted black. No insignia. No medallions. No name.